Consulting Case Studies and

Coaching Results

Study #1

$50 million annual turnover

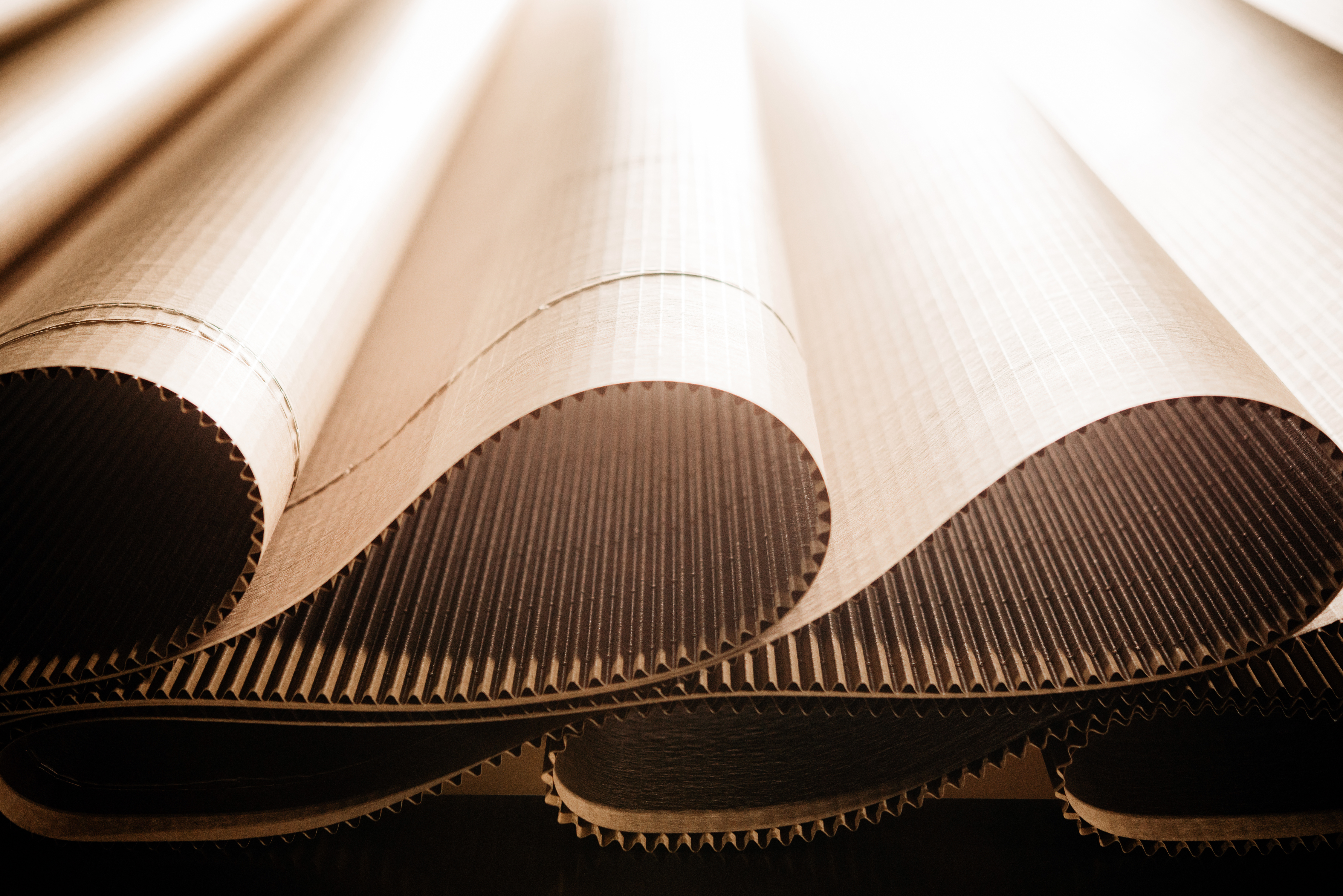

Paper and Packaging Manufacturing - Central Southwest U.S.A

The client is a major Central Southwest corrugated sheet supply facility with 80 employees running two shifts of production for packaging customers throughout the Central Southwestern marketplace. Client operated with long term supply contracts, and was unable to generate sufficient and acceptable positive cash flow.

This facility was experiencing excessive waste, late deliveries, poor product quality, and low morale. Employees were poorly trained, safety and housekeeping were not a priority, and owners were dissatisfied and demanding better results. The facility was losing $100k per month. The situation was critical, and needed to be rapidly turned around.

Process Steps | Solution

Staff training was conducted in lean manufacturing techniques:

Five S for Safety and Housekeeping

Total Preventive Maintenance (TPM)

Standardized Product Specifications

Quality System Deployment

Leadership training for building Trust.

Results

- Managed $300k per month improvement in profitability.

- Replace entire leadership team. Hired and trained new General Manager, Plant Manager, Financial Controller, and Customer Services Manager.

- Implemented JIT process for raw material. Reduced inventories by 40% or $1.2 million.

- Reduced waste from 17% to 8%, saving $140k per month.

- Increased throughput by 17%, adding $630k per month in revenues.

- Revised pricing to capture margin improvement on specialty items.

- Improved Gross Margin by 4%, resulting in annualized savings of $4 million overall.

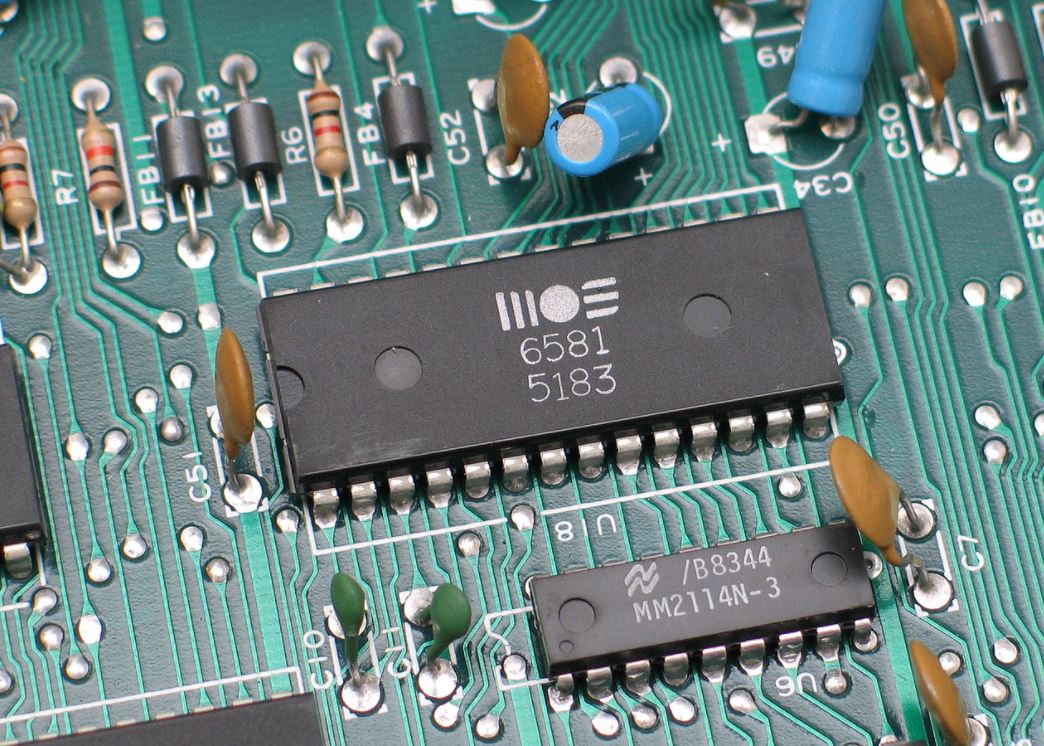

STUDY #2

Contract Manufacturing Company

$18 million annual turnover

This company assembles electronic components under contract for consumer and industrial product vertical industries. Over the prior 3 year time period, the company experienced some growth, but did not add corresponding value on the balance sheet. The leadership team was comprised of the founder and a few others that had been with the company since inception. The levels of gross and net margin were extremely low. The primary goal was rapid turnaround of quotes to any company issuing a request for quotation (RFQ). The CEO was actively engaged in the management of the business, and was unable or unwilling to delegate responsibility to staff.

Process Steps | Solution

Working with the CEO and COO, helped expand the leadership team, assigning each with functional accountabilities and key metrics. Increased revenues, profit, and cash flow, allowing company to expand and invest in plant and equipment, remaining debt free.

Results

- Implemented detailed planning process.

- Clarified Company Purpose, Core Values.

- Mapped key functions and assigned staff accountabilities and metrics.

- Facilitated the creation of a new and differentiated strategy.

- Redirected business development efforts to a specific core customer profile providing higher gross margins.

Study #3

Startup Packaging Company

$100 million annual turnover

Client represented five West Coast corrugated packaging converting facilities.

All five former competitors joined together and formed an LLC.

The LLC. was used to create a new corrugated sheet manufacturing facility to supply each member with their raw material, corrugated sheets, ensuring continuity of supply and reduced cost.

Process Steps | Solution

Working directly with the Board of Directors, Mr. Langhout provided services resulting in construction of a $27 million (gross assets) $60 million (annual turnover) corrugated sheet supply facility.

Results

- Negotiated 10 year lease on 256,000 sq.ft. building.

- Interviewed, hired, and trained initial staff of 62 employees.

- Participated in securing 8 figures non – recourse financing and 7 figures revolving line of credit.

- Participated in securing multiyear raw material supply agreement.

- Negotiated pricing and terms of purchase with equipment suppliers securing $15 million in equipment from vendors in U.S., Europe, and Japan.

- Managed successful startup of facility as General Manager for the initial five months after startup.

- In the years following startup, the company became the most productive and profitable in its industry category and exited to a strategic buyer, a Fortune 100 forest products company in 2015.

Avoid The Top 4 Killers of Your Online Business Dreams

In 80 minutes, discover exactly what mistakes you can be making that will stop your growth journey from succeeding - and what you should be doing instead. Register for our free webinar as we take a deeper dive into the 4 pillars of Growth, and build your One Page Plan.

Study #4

Facility Logistics and Office Relocation

$25 million annual turnover

The company had been in business over 20 years has two unrelated lines of service.

Known for their competence in getting the office and factory relocation projects completed on time and on budget with demanding customers, the company had an excellent reputation with customers in the marketplace.

However, internal problems persisted and threatened to disrupt operations.

Return on investment, gross margin, and cash, were dangerously low.

Turnover of personnel was high, and the culture was unacceptably dysfunctional.

Process Steps | Solution

The primary objective was to stop the turnover and improve the culture. Evaluated the competence and commitment of the entire leadership team; some were reassigned to other positions, and others were encouraged to leave the company and pursue other opportunities. A specific and differentiated strategy was developed that included new product lines which could be sold at higher margins. All key functions and processes were identified, mapped and targeted for improvement.

Results

- Implemented detailed planning process.

- Clarified Company Purpose, Core Values.

- Mapped key functions and assigned staff accountabilities and metrics.

- Facilitated the creation of a new and differentiated strategy.

- Redirected business development efforts to a specific core customer profile providing higher gross margins.

G3Growth Workshop